Another WorldInside Norton Motorcycles' impressive West Midlands HQ

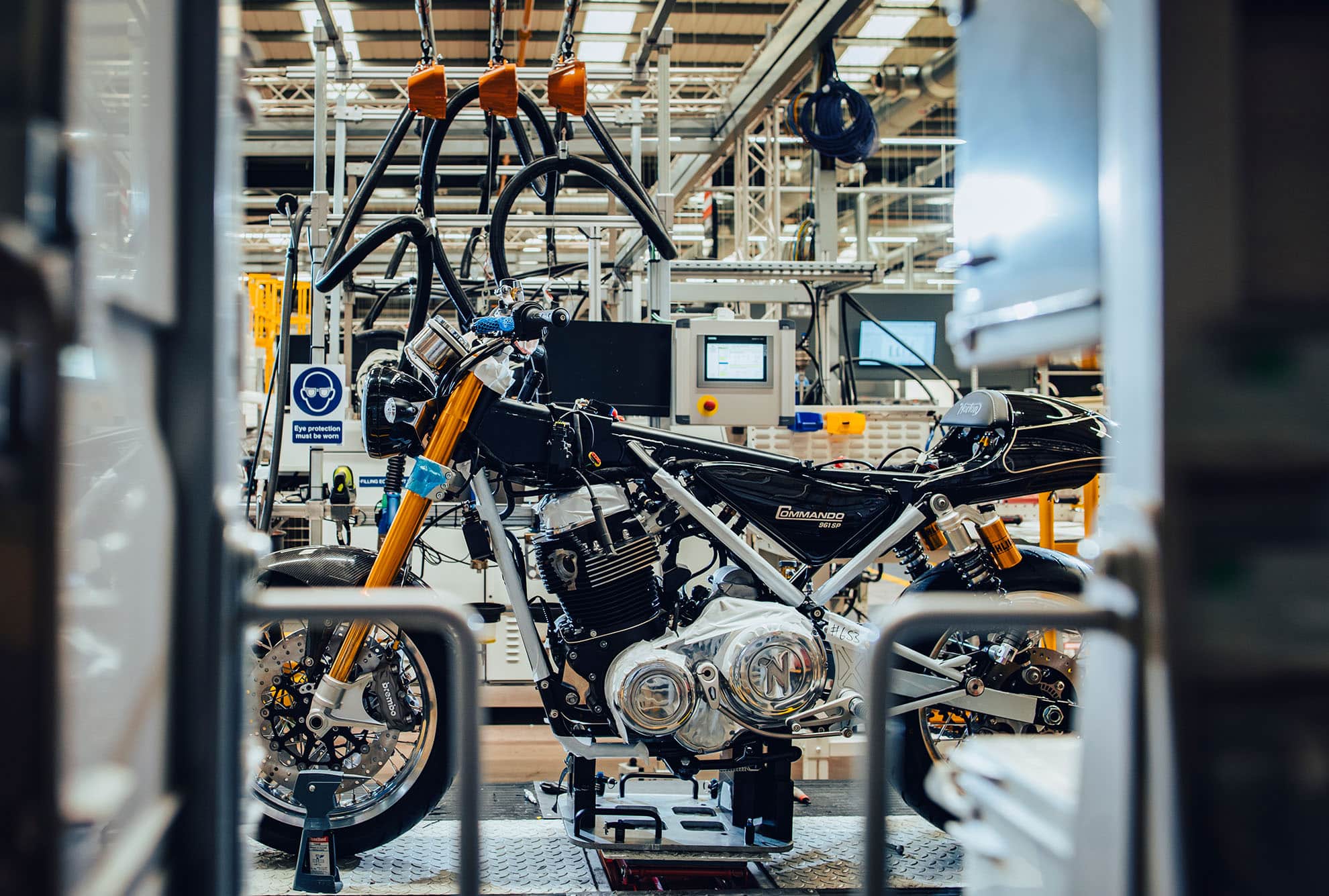

The Commando 961 is Norton’s traditional roadster.

Words by Gary Inman / Photos by Sam Christmas

While HebTroCo’s staff regularly visit mills and factories humming with the buzz of industrial sewing machines, I’ve spent a fair bit of time in automotive plants. Milwaukee; Bologna; Barcelona; Hofu, Japan; Chennai, India… From cutting-edge to small-scale, but not one as clean as Norton’s Solihull HQ. The reception is an atrium a five-star hotel would be proud of. The marque’s models, old and new, are on display. On the walls are billboard-sized, black-and-white images of Clint Eastwood and Honor Blackman astride Nortons.

Beyond a pair of turnstiles is the factory floor. Visitors to reception can peer straight in to catch a glimpse, but we are escorted further.

Norton is one of motorcycling’s many phoenix brands: a historic firm, gone out of business, its name and trademark eventually owned by an enthusiast, or enthusiasts in different regions, all with their own claim. AJS, Ariel, Brough Superior, BSA, Indian, Triumph… The list continues to grow as outfits try to breathe life back into increasingly obscure names.

Back in the 1990s, an American named Kenny Dreer was producing Nortons with his interpretation of the famous twin-cylinder engine. Dreer’s production bikes looked outwardly similar to Norton’s current Commando 961. His rights to the name and design were bought by Stuart Garner, a charming English crook..Garner’s charisma was immediately evident, his dishonesty took longer to surface, but he would eventually be found guilty of defrauding three pension schemes, of which he was the sole trustee, for £11 million. It is a sign of the power of the Norton name that Indian motorcycle giant, TVS, could see beyond the toxic bin fire left by Garner, and paid £16 million for the name and some of its assets. They also honoured debts to customers who had lost hefty deposits in the maladministration. How big are TVS? They sell 3 million bikes per year, and partner with BMW to build one model in India. So let’s have a look inside Norton…

A top-of-the-range V4SV

Look at that engine. A tot less than one litre of air-cooled charm. The Commando 961 is Norton’s traditional roadster, the descendent of the company’s most famous road bike, and a 21st-century two-wheeled E-Type. Wasp-waisted, feminine curves and tugboat torque. This one has high-spec suspension and brakes to ensure things remain civilised.

A top-of-the-range V4SV peers from the interrogation room of Final Inspection. The unblinking strip lights are designed to show every pore of the superbike. If you were paying £44,000 (or more for special editions), you might expect your bike to undergo this forensic scrutiny.

Above: The Mazak VTC-800 is a five-axis mill that can turn a microwave-sized block of high-grade aluminium alloy into a beautiful and structurally crucial piece of motorcycle in the time it takes you to cook a fried breakfast. At 5m in length, it is bigger than a suburban semi’s garage and costs twice as much as my house. It was working on new model prototypes when we visited.

Above: The welding bays look like a freshly-installed nightmare. In keeping with virtually everything else in Norton’s Solihull HQ, the welding department can be viewed through windows from walkways around the factory. There’s nowhere to swing the lead, have 40 winks, ten minutes with a newspaper, or any other cliché from the demise of the (original) British bike industry. Red ‘chiller blinds’ are there to stop onlookers being temporarily blinded by welding flash. Charlie adds to the sense of menace.

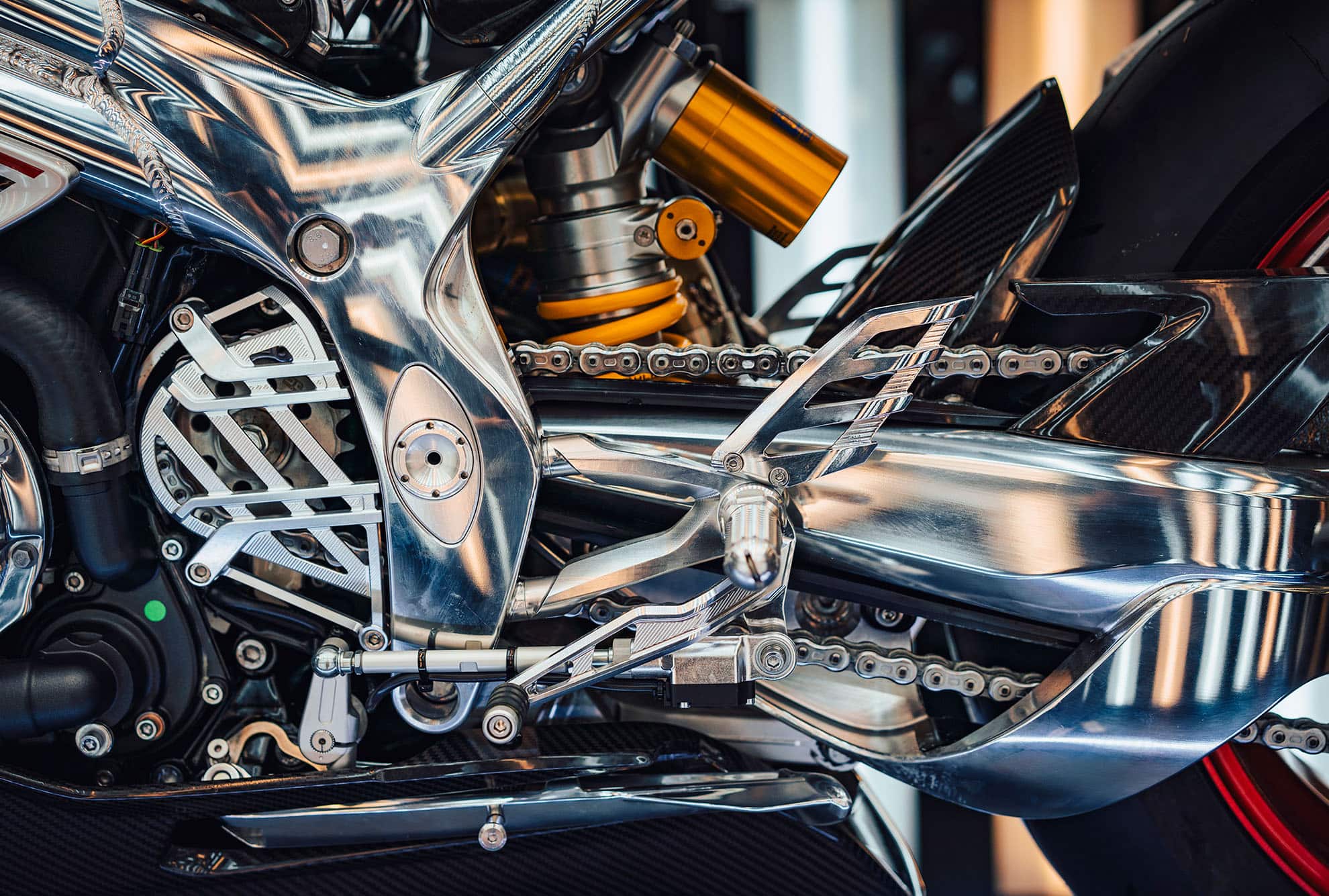

Above: Ray inspects the gleaming undercarriage of a V4SV. The sweatband is to protect the bike, not his watch, while a Norton-branded rubber cover ensures his wedding ring doesn’t inflict any damage. Pre-TVS Norton had a chequered recent history, and the new regime is determined not to let standards dip in the slightest. Everything about the factory has the air of being overseen by one of those detail-freak hotel managers featured in Channel 5 documentaries. The kind who irons his socks. To be clear, those are exactly the kind of people we want building our very expensive motorbikes.

Above: Anthony in the polishing room with a silencer. It sounds like a Cluedo guess. Anthony polishes various parts of each production bike by hand, giving Nortons a real air of craftsmanship. He’ll need help when they up production numbers from the current low rate of 350 per year.

While the Commando 961 is bought to ride, most V4 Nortons go into collections, becoming ornaments for men (always men, innit?) who can drop the best part of £50,000 on a motorcycle they’ll never use. I’m not going to judge. If it’s helping keep people employed, and this wonderful factory turning, then they can keep buying. Better than a Swiss watch of the same price. Norton will expand their range with new, more affordable models soon, because that huge investment needs to start paying for itself. Then things will really get interesting.

Words by Gary Inman / Photos by Sam Christmas

First published in Issue 3 of BOTHER magazine December 2024